Schedule Sync

Schedule Sync Documentation

Schedule sync is a mechanism that enables external control of machine scheduling. This functionality serves two independent purposes:

- Managing Order Hold Status: Orders can be placed on hold or recalled from machines, even if they are currently running.

- Order Sequencing: The order of execution for jobs on a machine can be externally defined.

Currently, schedule sync is implemented using SQL, with plans to introduce a webhook-style API in the future.

SQL Schema

| Field Name | Type | Size | Required | Description |

|---|---|---|---|---|

| order_ | varchar | 20 | Yes | Unique order identifier |

| material | varchar | 20 | Yes | Material associated with the order |

| pcode | varchar | 20 | Yes | Production code |

| onhold | tinyint | - | No | Indicates if the order is on hold (1 = Yes, 0 = No) |

| machinenum | int | - | No | Machine number assigned to the order |

| sequence | int | - | No | Sequence number determining execution order |

| sqlplant | varchar | 3 | No | Plant identifier |

Setting Order Hold Status

This feature allows an external system (e.g., ERP) to control the hold status of orders without relying on integration middleware to detect and apply changes.

- Orders Not Yet Sent to a Machine: Placing an order on hold prevents it from being assigned to a machine. A scheduled order will remain in the schedule but will be skipped.

- Orders Already at a Machine: Setting an order on hold recalls it from the machine. If the order is currently running, the machine will be halted before recalling the order.

Hold Jobs Not In Sync Data

This option places all existing orders on hold if they are absent from the source data. If an order is deleted from the ERP, this setting ensures that it is held. While this behavior is often desirable, manually entered test orders will also be continuously held.

Order Sequencing

Preliminary: Subject to change. Please contact AMS if this feature is of interest.

Schedule Sync uses the machinenum and sequence fields to externally control machine scheduling. The sequence number serves as a sorting key rather than a fixed position and does not need to be contiguous.

Key Considerations:

- Affects Only Unsynchronized Orders: Sequence and assignment changes only apply to orders that have not been sent to the machine. To minimize the number of orders at a machine, we recommend enabling the Auto-Push feature.

- Manual Recall Required for Sent Orders: Once an order has been sent to a machine, it must be manually recalled or placed on hold for resequencing.

- Sync Data Priority: Orders present in the sync data are sequenced ahead of orders not included in the sync data.

- Unscheduled Orders: Orders with

machinenumset to0will be unscheduled.

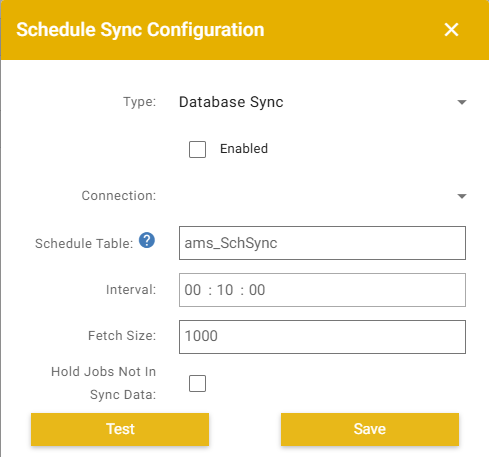

Configuration