Coil Validation

Coil validation helps to avoid costly mistakes by choosing the wrong coil for an order. In Eclipse, the Material Code or Coil Type defines a code that specifies all the important properties of a coil. In ERP systems this is sometimes referred to an item master. In addition to metal type, gauge, coating/paint, etc., it also includes the width of the coil. When choosing a coil based on the material code, it shouldn't matter which coil gets selected. There might be other process reason why some coils are preferred over others (age, consignment, etc.) but the final product shouldn't changed if the material code is correct.

Coil validation consists of two steps. The first step, a coil serial number is entered into XL controller. A request is made to Eclipse to identify the material code of that serial number. There are several methods for doing this. Regardless on the method, there are at least two possible outcomes to the request:

- Valid: The serial number was found and it has a material code

- Not Found: The serial number was not found

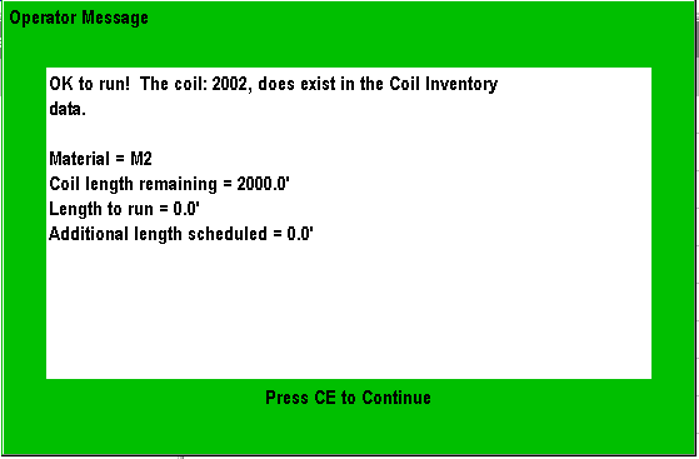

If the request coil is found to be valid, Eclipse will send the material code to the controller and it will be displayed in the coil screen of the XL. If the coil is not found, that material code will remain blank. At this point, Eclipse has only established that the coil does exist and not that it is the correct coil to be run for the job. That happens next.

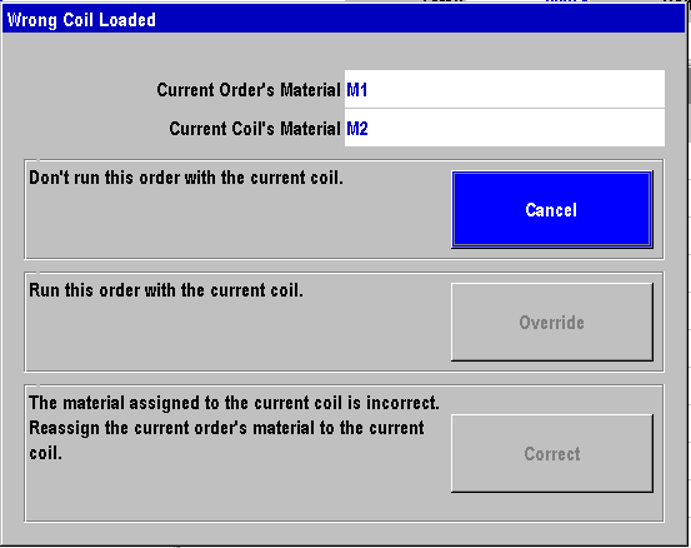

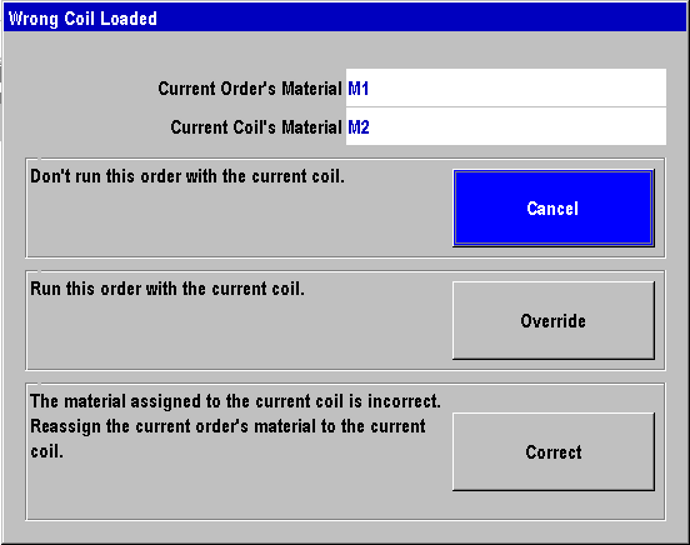

The second step happens when the operator starts the machine. The controller compares the material code specified in the order to the material code that Eclipse found for that coil. If they match, the machine is allowed to run. If they don't match, the machine does not go into run. Depending on the system configuration, the operator might be prompted with a choice to override the validation. This might be required for a few scenarios:

- The coil database is not accurate.

- The coil database does not yet have the coil information entered yet.

- There is an approved material override (heavier gauge for example)

Diagram:

Configuration

There are a number of settings that interact with coil validation:

- Eclipse

- Settings > General > Controllers

- Verify coils when loaded

- Disable coil OK to run message

- Settings > General > Controllers

- XL

-

Machine Parameters

- Use Coil Inventory

- Yes *

- Uses the Controllers Coil Inventory-When Coils are "Returned to Inventory" they remain in the Controller Production Data button-->Coil Inventory

- No

- The controller does not prompt for a coil number when the tail-out input is turned ___

- All other coil related parameters are removed

- Production Data > Coil Inventory is removed

- Remote

- Uses Eclipse/SQL Coil Inventory-When Coils are "Returned to Inventory" they do not remain in the Controller Production Data button-->Coil Inventory

- Yes *

- Allow Coil Override

- Always

- Only With Key *

When "Remote" is selected in "Use Coil Inventory", you can Override the Coil selection by turning the Setup-Lockout to off using the Setup-Lockout key.

- Controller Settings > Eclipse Settings

- Enforce Eclipse Coil Validation

- Yes *

- No

- Enforce Eclipse Coil Validation

- Use Coil Inventory

-

With Eclipse Pro and newer XL firmware versions, it is possible to set and enforce the XL parameters from the office.

Minimum 4.58.0 Recommended 4.88.0+

Sample screenshots:

Wrong coil loaded, locked out:

Wrong coil loaded, Manager override:

Coil Found message: